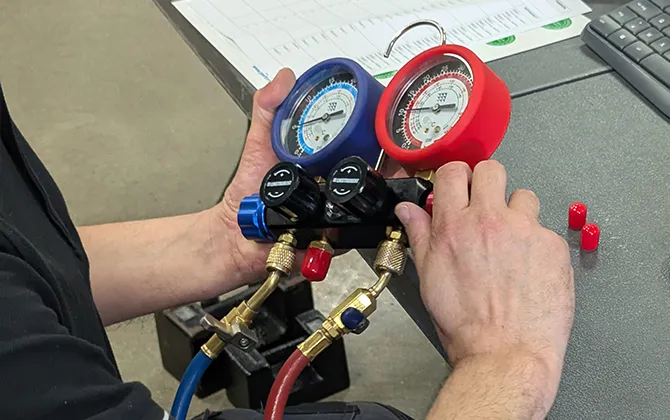

Vacuum pumping is one of the most critical steps when commissioning a refrigeration or air conditioning system. A properly sized vacuum pump ensures effective drying of the circuit, removes residual moisture, evacuates non-condensable gases, and helps protect the compressor for long-term reliability. But how do you choose the right vacuum pump based on system size and the refrigerant used?

Why is choosing the right vacuum pump essential?

An undersized pump leads to:

• a very long evacuation time,

• an inability to reach the target vacuum level (e.g., 500 microns),

• a risk of residual moisture → acids → compressor damage,

• poor long-term energy efficiency.

An oversized pump, on the other hand, is not dangerous, but it can be unnecessarily expensive and less convenient to transport.

The right choice therefore depends on three factors:

1. The internal volume of the circuit (piping + indoor/outdoor units + accessories),

2. The type of installation (split, multi-split, heat pump, etc.),

3. The refrigerant (notably R32 = A2L and R290 = A3).