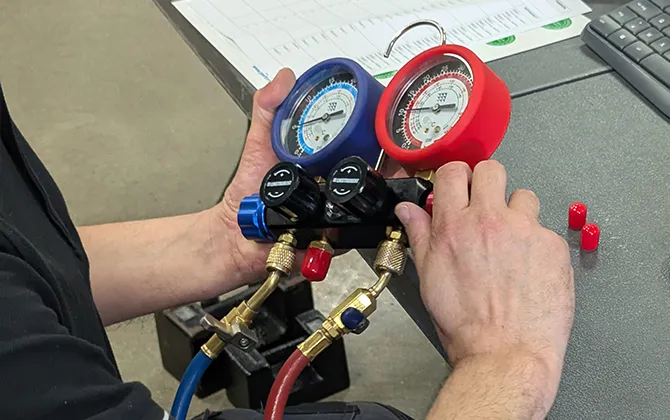

In the HVAC-R and refrigeration sector, tools are the daily companions of technicians. Whether it’s a manifold, a vacuum pump, a leak detector, or charging hoses, these instruments are exposed to intense working conditions. Poor maintenance can quickly reduce their efficiency, lead to measurement errors, or even cause costly breakdowns. Regular tool maintenance is not an option—it’s a necessity. It ensures not only reliability and accuracy but also safety during interventions and the profitability of your business. Here are 10 best practices to extend the lifespan of your HVAC-R tools.

1. Clean your tools regularly

Dust, oil residues, and refrigerant deposits can affect performance. After each job, carefully wipe down your tools and, if necessary, use a suitable cleaner to prevent corrosion.

2. Check hose tightness

Hoses are subject to high pressure and may lose effectiveness over time. Regularly inspect seals and fittings to detect potential leaks.

3. Protect electronic instruments

Leak detectors, thermometers, and digital manifolds should be stored in their protective cases to avoid shocks and moisture. Never leave them lying around on site.

4. Perform regular calibration

Measuring tools such as leak detectors or charging scales require periodic calibration to ensure accuracy. Follow the manufacturer’s recommendations and respect the intervals.

5. Store in proper conditions

A clean, dry location protected from extreme temperature changes is ideal for tool storage. Moisture is the number one enemy of electronic circuits and metal parts.

6. Check oil levels and vacuum pump condition

Vacuum pumps require regular checks of oil levels (if applicable) and overall operation. Replace the oil as soon as it becomes cloudy or contaminated.

7. Use tools as intended

Never divert a tool from its original purpose. For example, a high-pressure hose should not be used as an unsuitable transfer hose, as this may cause premature damage.

8. Avoid overloads

Always respect the manufacturer’s limits: maximum pressure, admissible load, operating temperature. Overloading accelerates wear and poses risks for the operator.

9. Inspect overall condition regularly

A quick visual check can prevent many issues. Inspect electrical cables, connectors, filters, and fasteners. Any abnormal wear should be addressed immediately.

10. Train technicians in tool maintenance

Well-maintained tools start with good user practices. Take the time to train your teams in proper handling and maintenance procedures.

Conclusion

A technician equipped with reliable, well-maintained tools works more efficiently, safely, and with precise results. Taking care of HVAC-R equipment means investing in durability, reducing replacement costs, and ensuring customer satisfaction. By applying these 10 simple yet essential tips, you maximize your tools’ performance and guarantee their longevity over the long term.