Which ATEX tools are needed for working with R290?

When servicing systems charged with R290, it is essential to be equipped with a complete set of ATEX-certified tools covering every stage of the intervention. Below are the main categories of equipment, with references available from LINSTRUMENT.

- Ventilation and Air Renewal

An ATEX fan ensures safe evacuation of propane vapors, preventing gas accumulation.

➡ BLW-250-EX – 25 m³/min airflow, robust steel frame, certified Ex db IIB T4 Gb.

- Gas Detection and Monitoring

An ATEX explosimeter continuously monitors gas concentration and alerts the technician when critical thresholds are reached.

➡ YT-1200H-S-R290 – clear %LEL display, configurable alarms.

- Flammable Refrigerant Recovery

Recovering R290 requires a reliable, spark-proof ATEX recovery station.

➡ TREK-POWER-EX – brushless 1.3 HP station, certified ATEX Ex II 3G.

- Brazing and Nitrogen Inerting

An ATEX pressure regulator ensures safe brazing and inerting during work on systems charged with A3 refrigerants.

➡ PRG-125 – manual regulator/flowmeter (0–30 L/min), stainless steel build, compact, supplied in carrying case, European-made with French quality control.

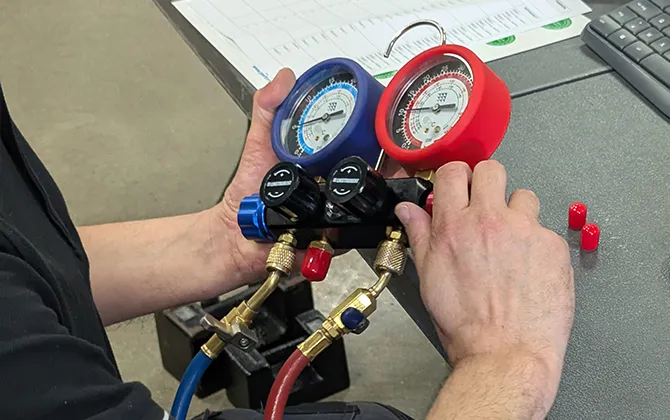

- Pressure Measurement and Control

A manifold compatible with R290 must be both robust and precise.

➡ MG-470-PAC – 4-way analog manifold with oil-filled gauges, supplied with adapted hoses.

- Secure Hoses and Accessories

Zero-emission hoses reduce refrigerant releases and protect technicians during interventions.

➡ VZE Hoses – pivoting design, zero-emission valve, dual nitrile O-rings.

Conclusion

R290 offers many advantages in terms of performance and environmental impact, but its flammability requires absolute vigilance. Following strict safety procedures and relying exclusively on ATEX-certified tools is not optional—it is a necessity. The ATEX range offered by LINSTRUMENT—fans, explosimeters, recovery stations, nitrogen regulators, manifolds, and hoses—provides a complete and reliable solution for working safely with A3 refrigerants such as R290. By choosing ATEX-certified equipment, you protect your teams, ensure regulatory compliance, and guarantee safe and professional interventions.